Irish manufacturing, including life sciences, stands on the cusp of a technological revolution that could see the bottom line transformed as much as technology.

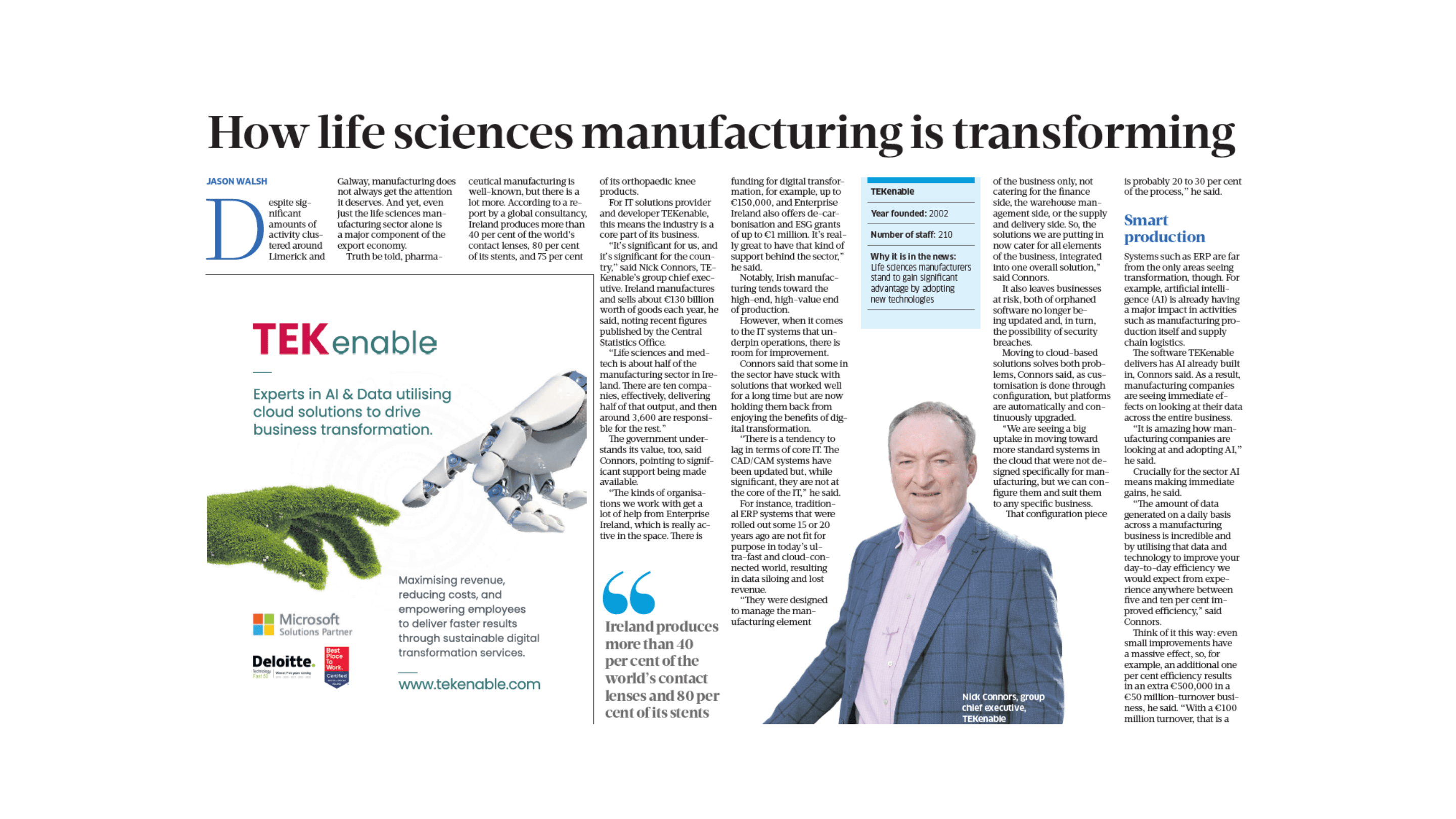

Nick Connors, Group Chief Executive, TEKenable

Despite significant amounts of activity clustered around Limerick and Galway, manufacturing does not always get the attention it deserves. And yet, even just the life sciences manufacturing sector alone is a major component of the export economy.

Truth be told, pharmaceutical manufacturing is well-known, but there is a lot more. According to a report by a global consultancy, Ireland produces more than 40 per cent of the world’s contact lenses, 80 per cent of its stents, and 75 per cent of its orthopaedic knee products.

For IT solutions provider and developer TEKenable, this means the industry is a core part of its business.

“It’s significant for us, and it’s significant for the country,” said Nick Connors, TEKenable’s group chief executive. Ireland manufactures and sells about €130 billion worth of goods each year, he said, noting recent figures published by the Central Statistics Office.

“Life sciences and medtech is about half of the manufacturing sector in Ireland. There are ten companies, effectively, delivering half of that output, and then around 3,600 are responsible for the rest.”

The government understands its value, too, said Connors, pointing to significant support being made available.

“The kinds of organisations we work with get a lot of help from Enterprise Ireland, which is really active in the space. There is funding for digital transformation, for example, up to €150,000, and Enterprise Ireland also offers de-carbonisation and ESG grants of up to €1 million. It’s really great to have that kind of support behind the sector,” he said.

Notably, Irish manufacturing tends toward the high-end, high-value end of production.

However, when it comes to the IT systems that underpin operations, there is room for improvement.

Connors said that some in the sector have stuck with solutions that worked well for a long time but are now holding them back from enjoying the benefits of digital transformation.

“There is a tendency to lag in terms of core IT. The CAD/CAM systems have been updated but, while significant, they are not at the core of the IT,” he said.

For instance, traditional ERP systems that were rolled out some 15 or 20 years ago are not fit for purpose in today’s ultra-fast and cloud-connected world, resulting in data siloing and lost revenue.

“They were designed to manage the manufacturing element of the business only, not catering for the finance side, the warehouse management side, or the supply and delivery side. So, the solutions we are putting in now cater for all elements of the business, integrated into one overall solution,” said Connors.

Ireland produces more than 40 per cent of the world’s contact lenses and 80 per cent of its stents

It also leaves businesses at risk, both of orphaned software no longer being updated and, in turn, the possibility of security breaches.

Moving to cloud-based solutions solves both problems, Connors said, as customisation is done through configuration, but platforms are automatically and continuously upgraded.

“We are seeing a big uptake in moving toward more standard systems in the cloud that were not designed specifically for manufacturing, but we can configure them and suit them to any specific business. That configuration piece is probably 20 to 30 per cent of the process,” he said.

Smart production

Systems such as ERP are far from the only areas seeing transformation, though. For example, artificial intelligence (AI) is already having a major impact in activities such as manufacturing production itself and supply chain logistics.

The software TEKenable delivers has AI already built in, Connors said. As a result, manufacturing companies are seeing immediate effects on looking at their data across the entire business.

“It is amazing how manufacturing companies are looking at and adopting AI,” he said.

Crucially for the sector AI means making immediate gains, he said.

“The amount of data generated on a daily basis across a manufacturing business is incredible and by utilising that data and technology to improve your day-to-day efficiency we would expect from experience anywhere between five and ten per cent improved efficiency,” said Connors.

Think of it this way: even small improvements have a massive effect, so, for example, an additional one per cent efficiency results in an extra €500,000 in a €50 million-turnover business, he said. “With a €100 million turnover, that is a million euro,” he said.

The above text was reproduced from the interview published in BusinessPost on May 10th, 2024.